FabHydro: Printing Interactive Hydraulic Devices with an Affordable SLA 3D Printer

We introduce FabHydro, a set of fabrication methods to democratize the printing of hydraulic-driven mechanical devices with consumer-grade 3D printers that cost less than 200 US dollars.

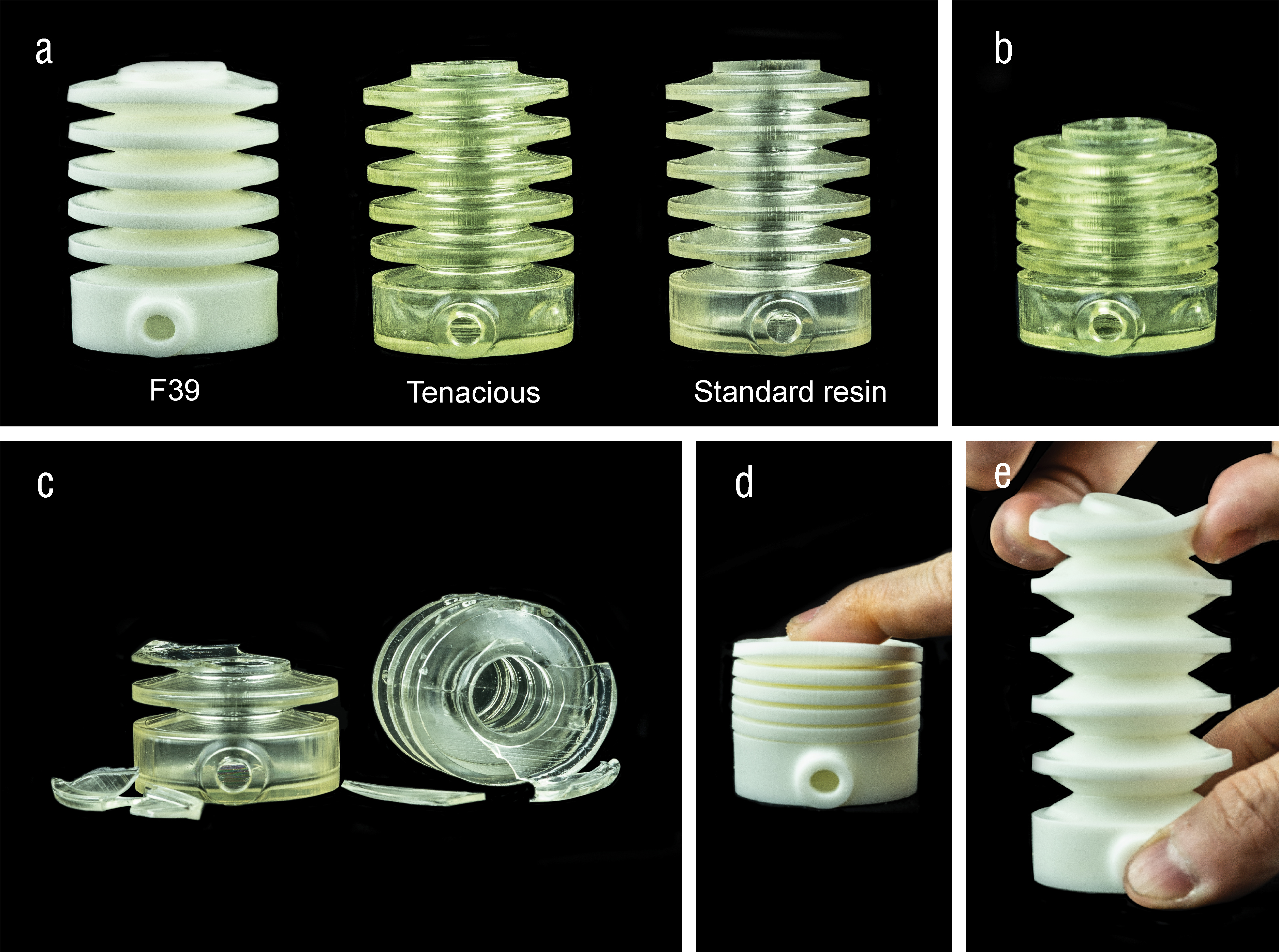

Our core idea centers on low-cost stereolithography (SLA) printers, which can produce both stiff and flexible structures from a selected photosensitive resin in one printing process.

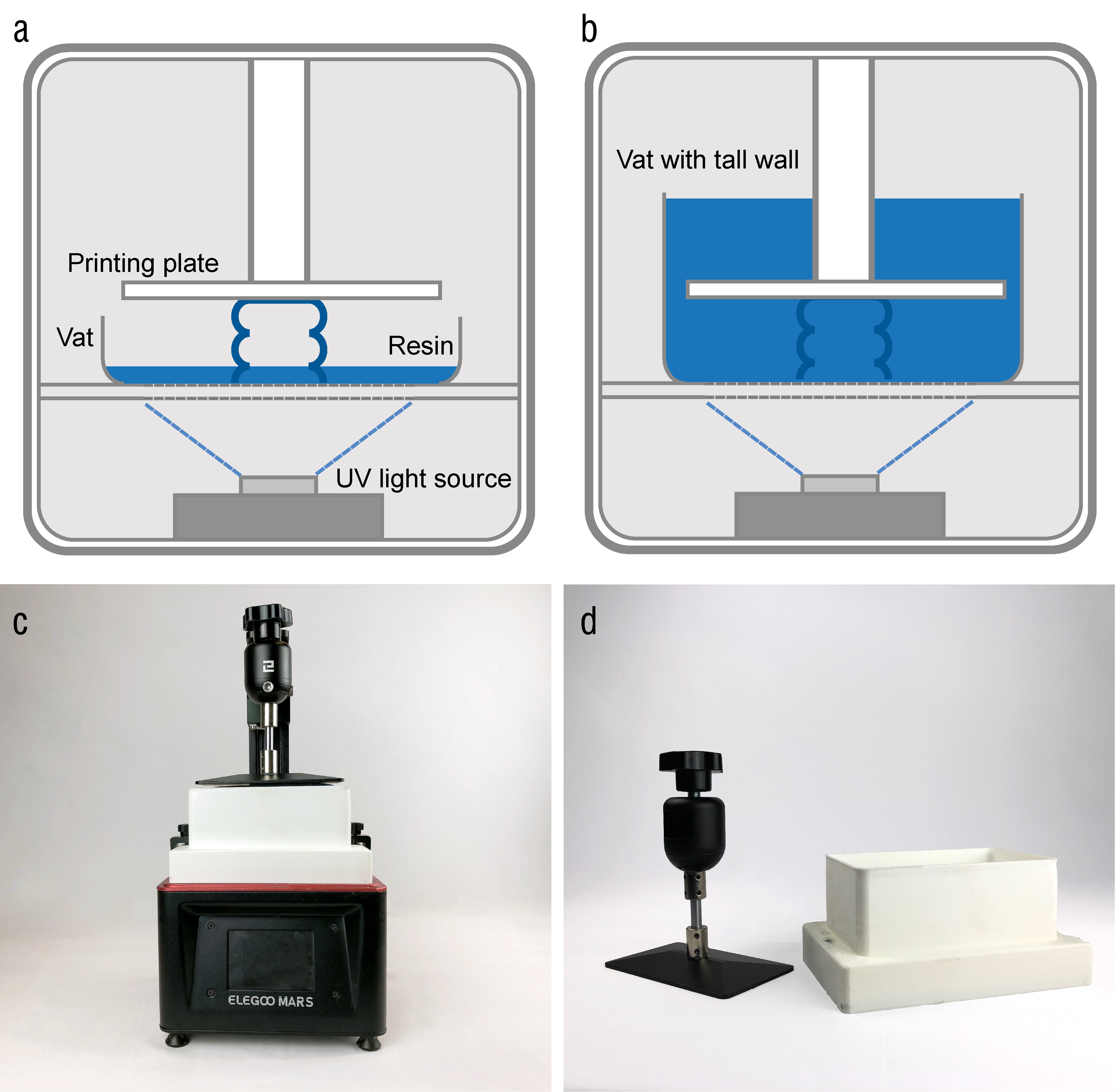

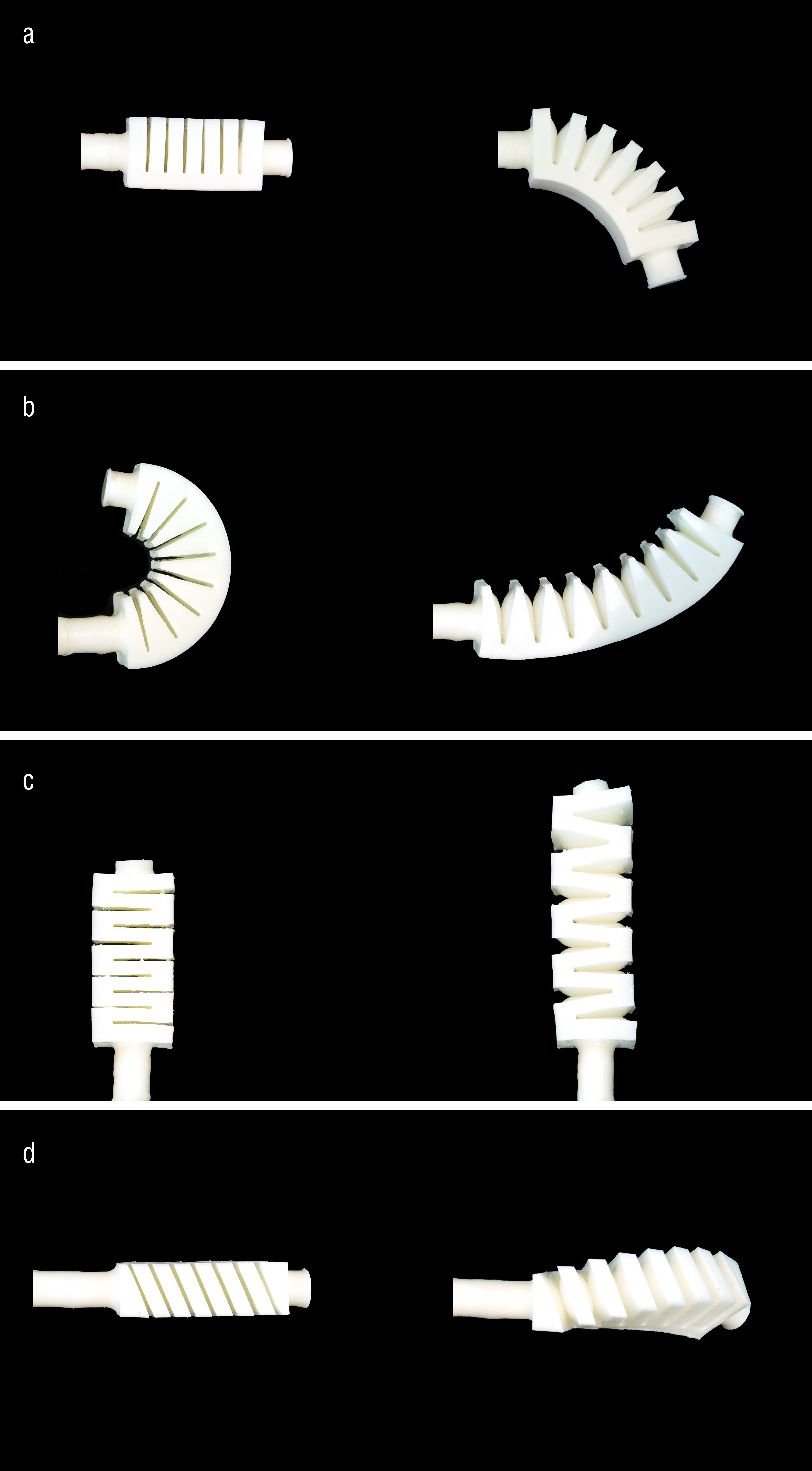

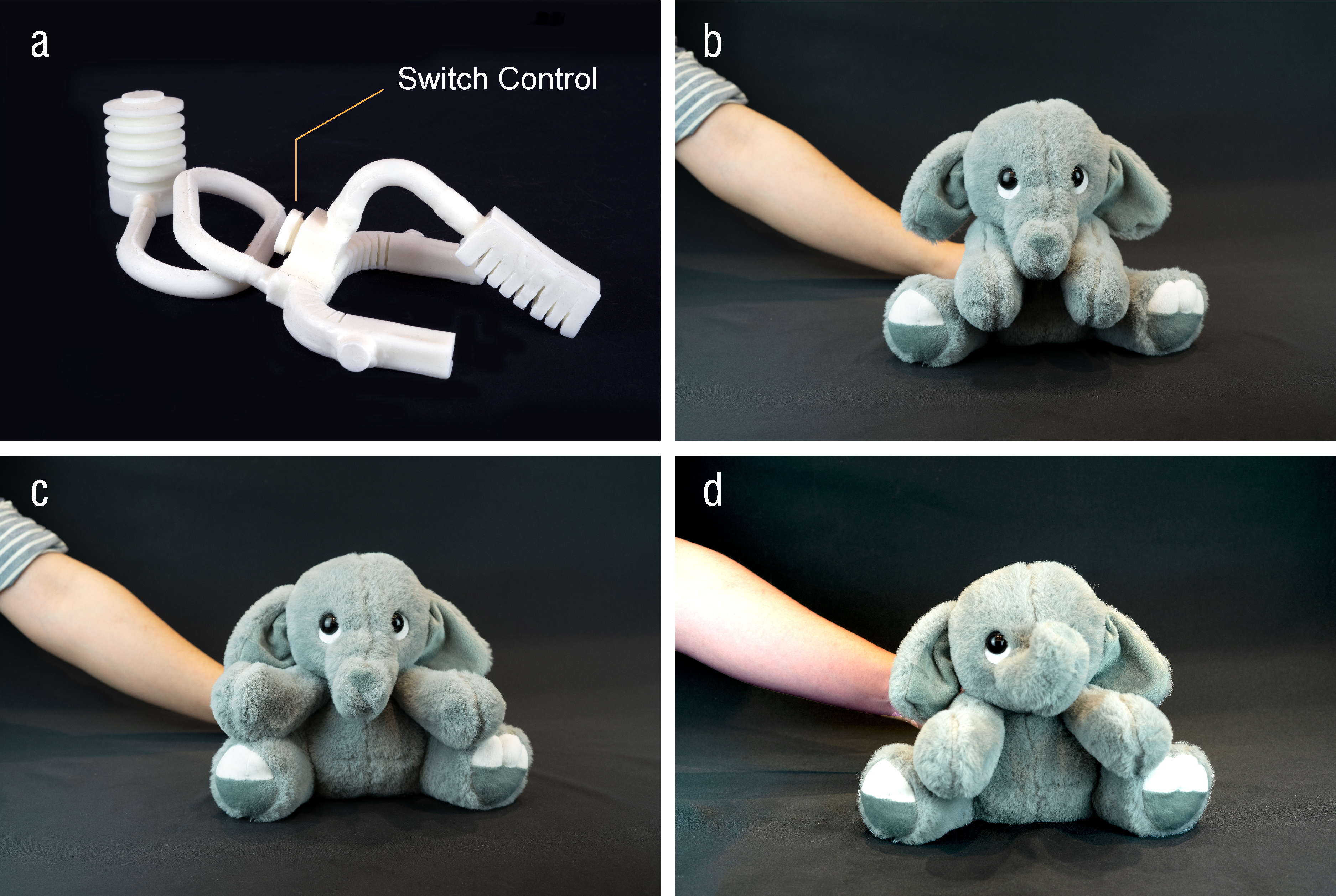

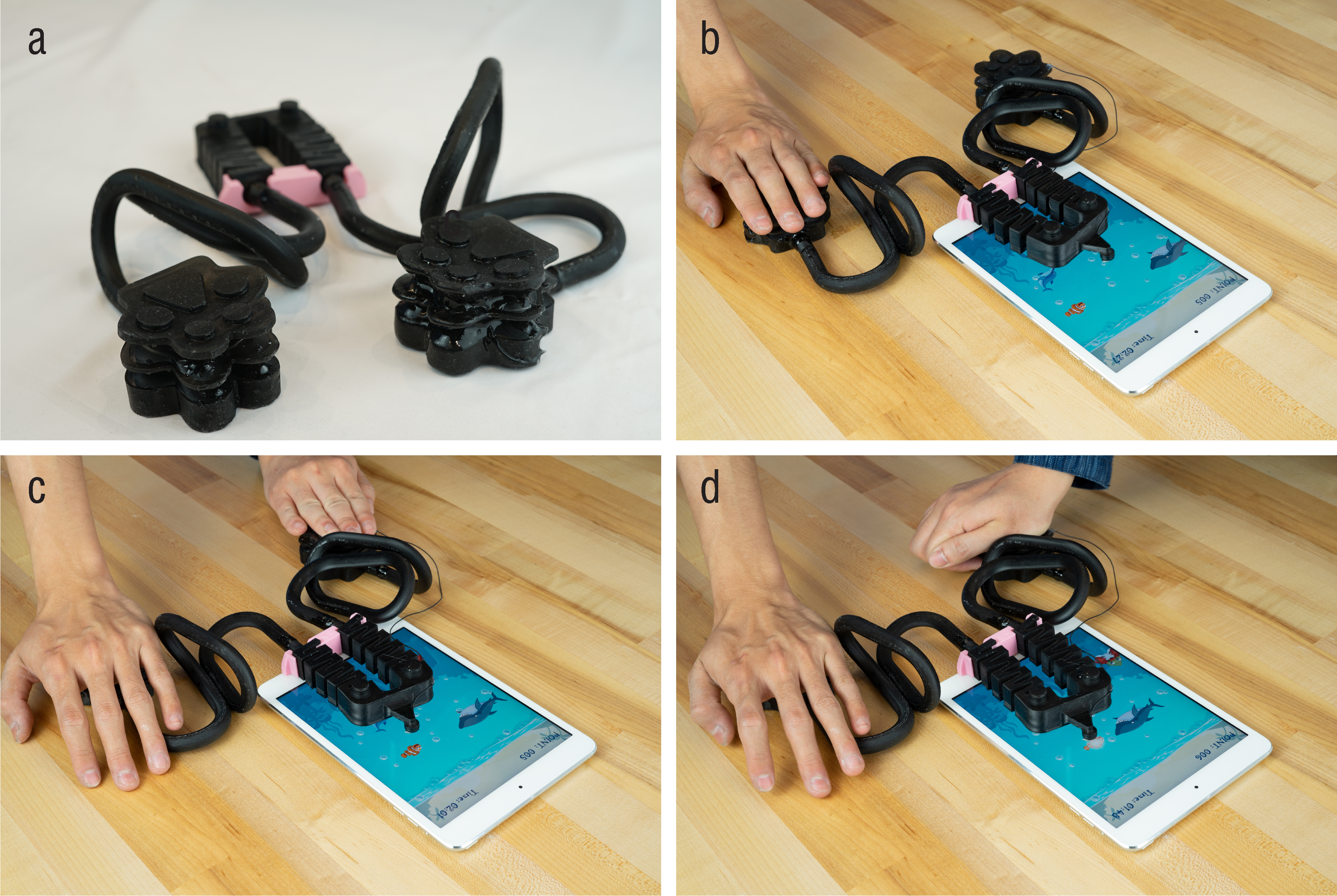

We first present printer settings and custom support structures to warrant the successful print of flexible and deformable objects.

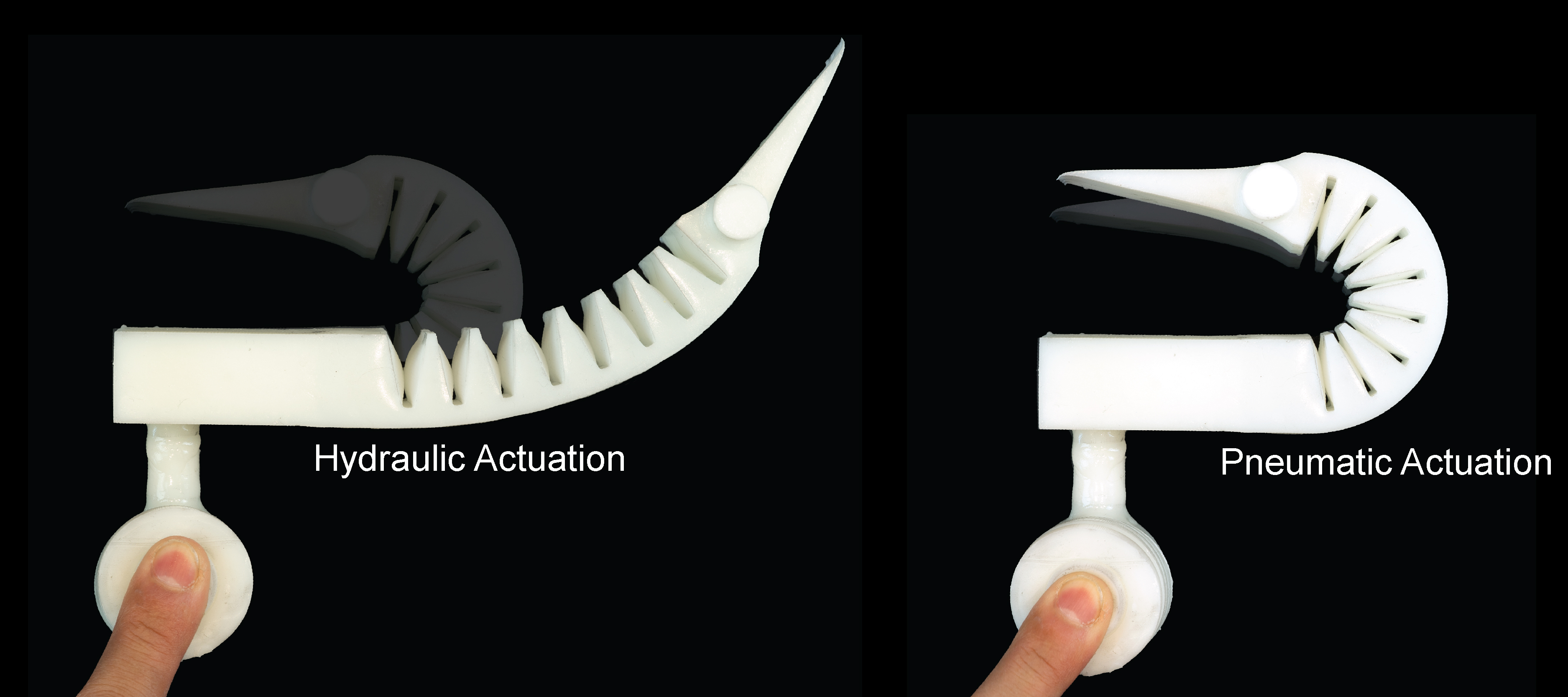

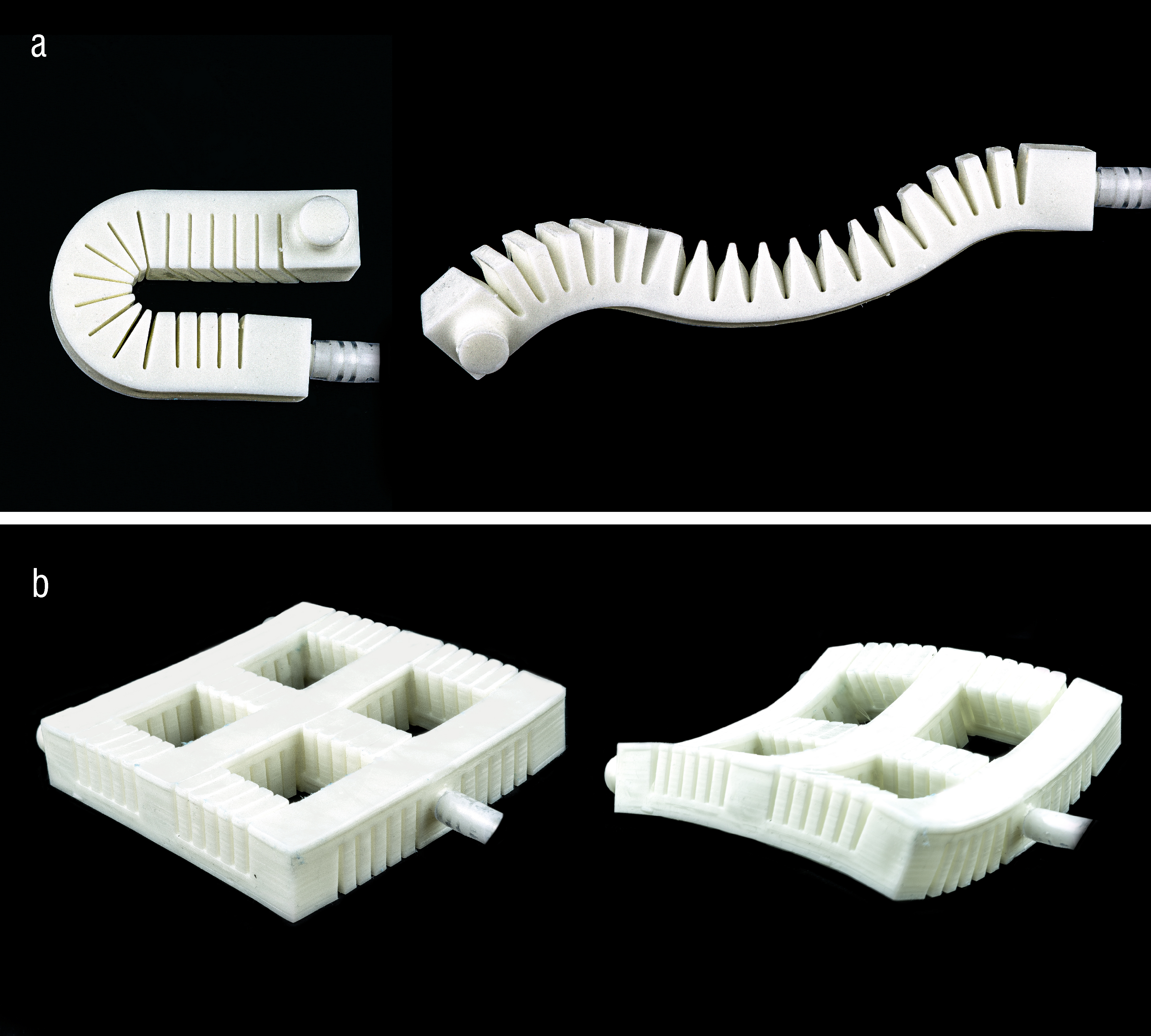

We then detail two optional printing processes that seal the hydraulic liquid inside. With the first process, which we called Submerged Printing, the entire hydraulic device, including the mechanical and the fluid inside, can be printed all at once with a slightly modified printer vat. This is suitable for printing hydraulic prototypes for fast design iteration, as the printed device requires no manual assembly and is ready to test out-of-the-printer.

The second process, which we called Printing with Plugs, allows the user to fill water or other liquids inside the printed chamber and seal them with printed plugs as a post-process. The benefit of this method is that it requires no hardware modification to the printer. However, printed objects require manual assembly.

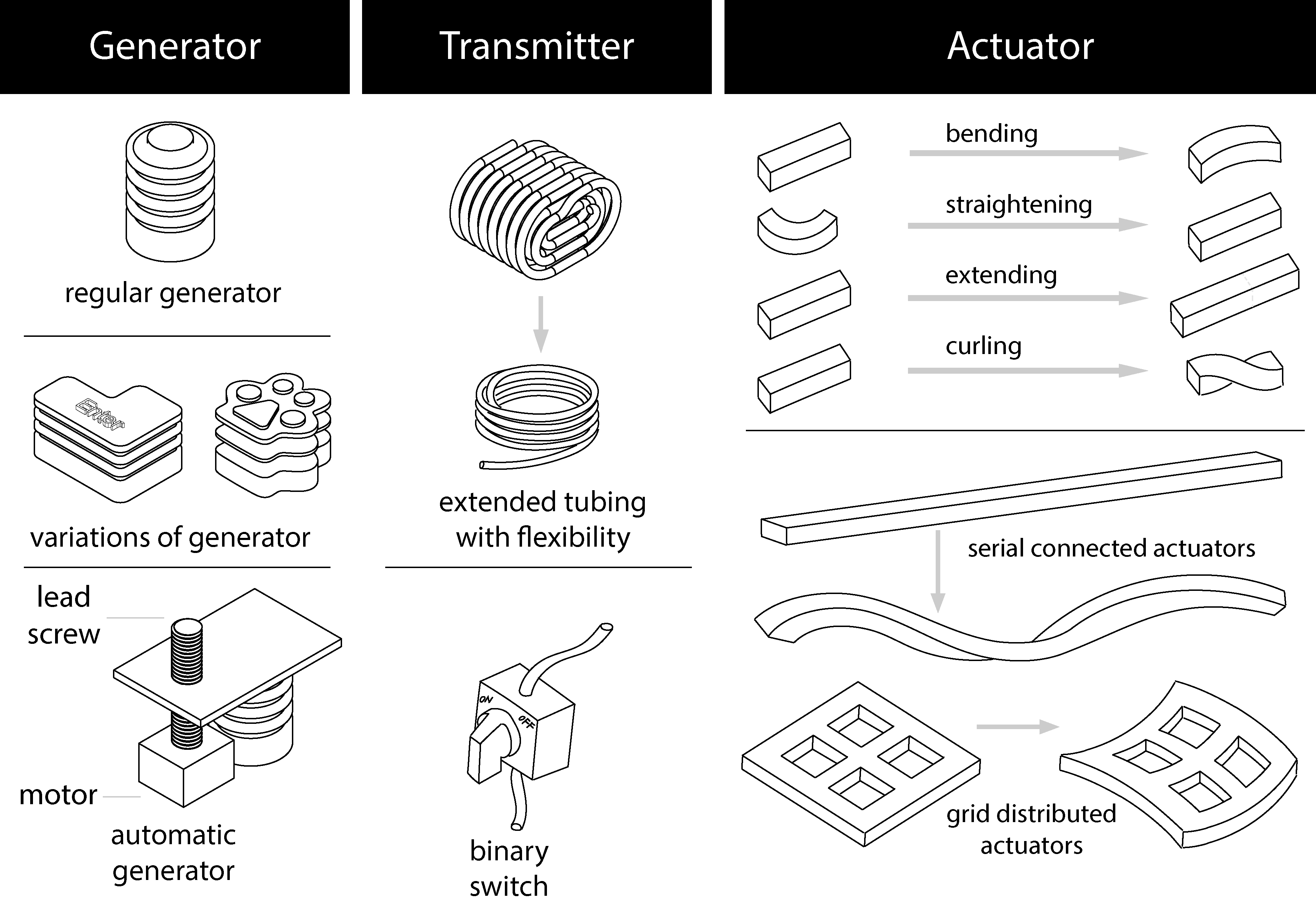

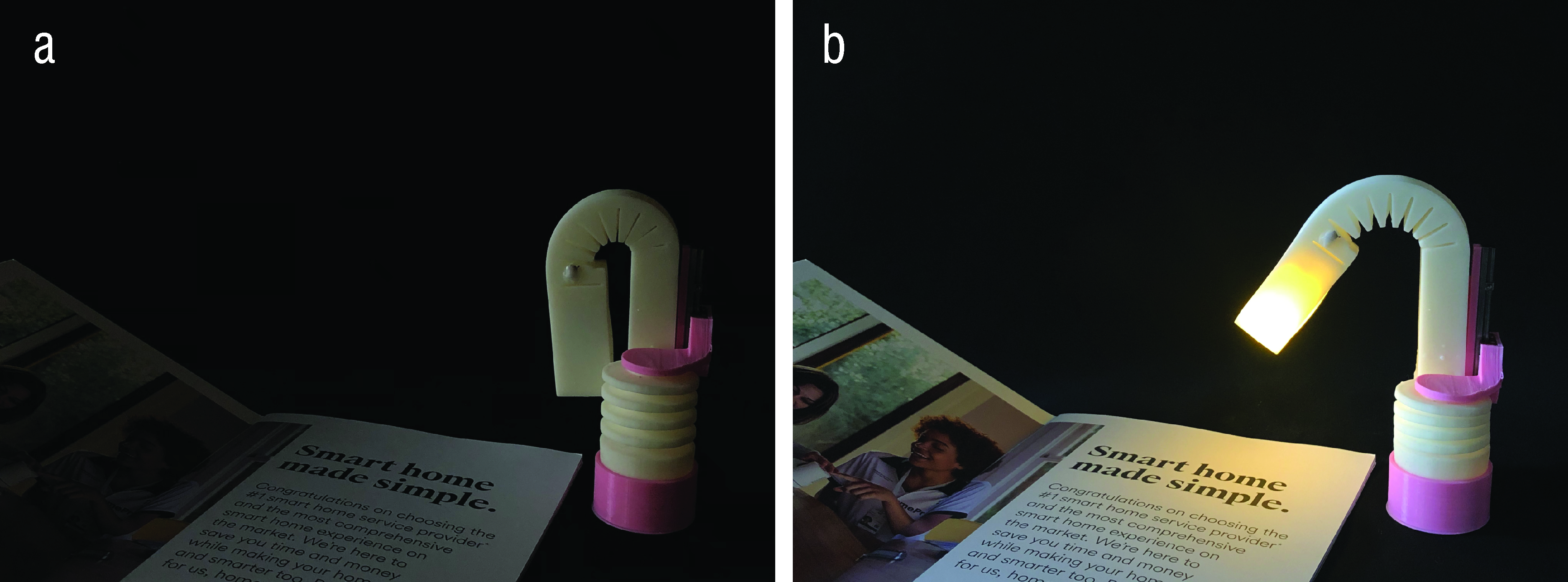

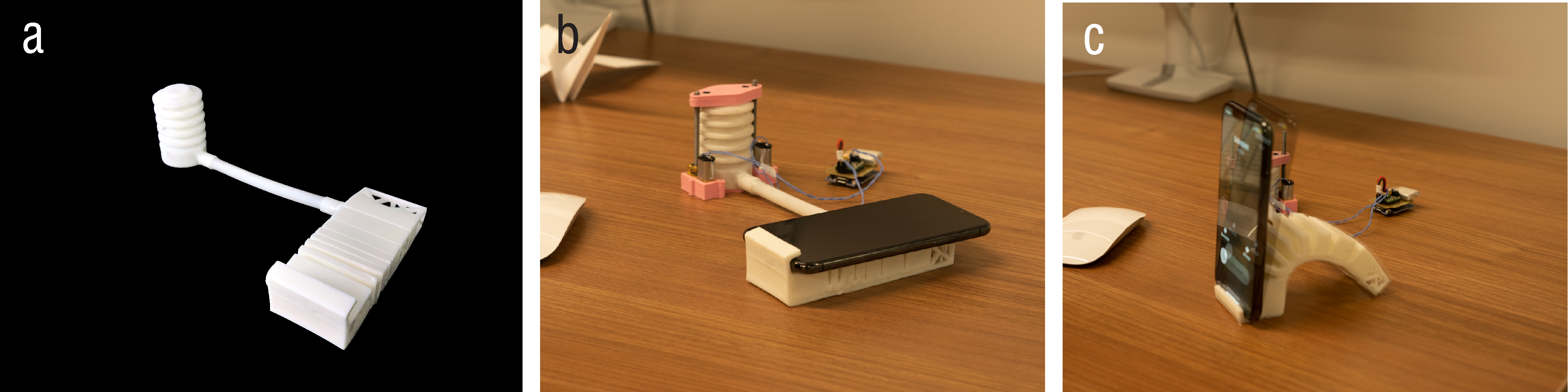

Following the printing methods, we report a design space with a range of 3D printable primitives, including the hydraulic generator, transmitter, and actuator. To demonstrate the feasibility of our approaches and the breadth of new designs that they enable, we showcase a set of examples from a printed robotic gripper that can be operated at a distance to a mobile phone stand that serves as a status reminder by repositioning the user’s phone. We conclude with a discussion of our approach’s limitations and possible future improvements.

Created by:

Zeyu Yan, Huaishu Peng.

Research Paper:

In Proceedings of UIST '21.